Pianta s.r.l.

Welcome

Our Production

Wood supply

We select high-quality timber from the forests around Lake Maggiore.

Raw wood

The process begins with raw wood, freshly cut and still in its natural form. Each log is inspected to ensure integrity and no structural defects.

Log cutting

Logs are cut into planks with precision machinery, optimizing material yield and preparing the wood for subsequent processing stages.

Wood drying

The timber is brought to ideal moisture through a controlled natural drying process, and subsequently in drying chambers. The entire process can last up to 21 days.

First wood processing

The wood is planed with a machine that prepares the planks for shaping.

Plank gluing

The planks are glued together to form larger panels, using formaldehyde-free vinyl glue, ensuring solidity and durability.

Shaping

Thanks to the latest high-precision profiling machine, the surfaces are prepared for final assembly.

Coffin assembly

The wooden parts are carefully assembled to construct the coffin structure, ensuring solidity, symmetry, and proportion.

Quality control

Each coffin undergoes a final manual inspection to ensure an elegant appearance consistent with company quality standards.

First coat of varnish

The coffin receives the first coat of varnish.

Sanding

Expert craftsmen manually intervene after the first coat of varnish to remove all irregularities.

Varnishing in closed cabin

The varnishing, glossy or satin, takes place in a closed cabin to ensure uniform and controlled application without impurities.

Final quality check

Each coffin is rigorously checked before packaging, and if it passes all tests it is prepared for shipment.

Finished coffin

Example of finished coffin before packaging.

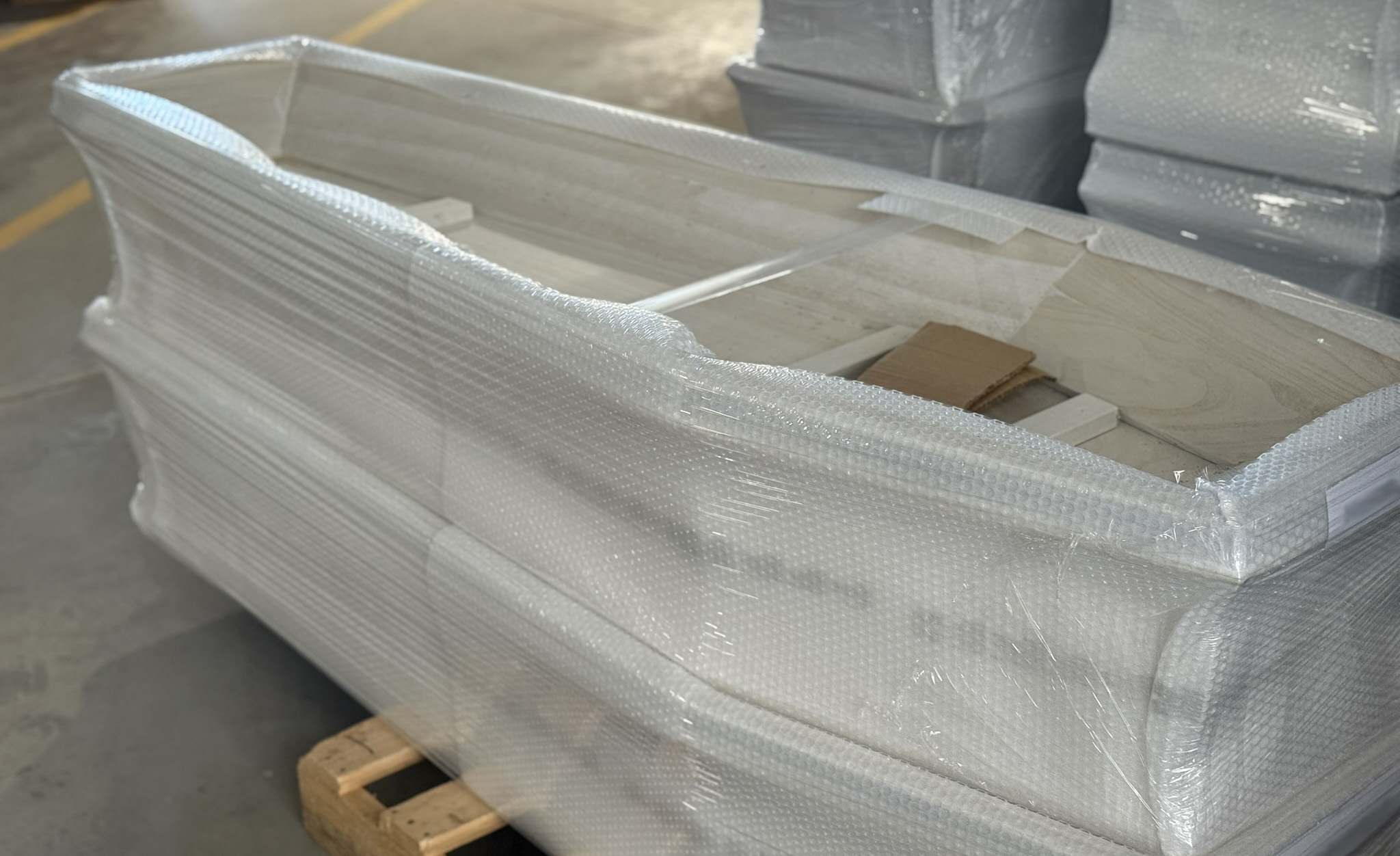

Coffin packaging

The coffin is packed with protective materials, including bubble wrap and reinforced cardboard, ensuring integrity and safety during transport.